Maintaining the integrity of underground piping systems is essential for the smooth functioning of residential, commercial, and industrial properties. However, over time, pipes can deteriorate due to various factors such as age, corrosion, tree root intrusion, or ground shifting. Traditional methods of pipe relining or replacement often involve extensive excavation, leading to disruption, inconvenience, and high costs. Fortunately, pipe relining offers a modern, efficient, and cost-effective solution to address these issues. In this comprehensive guide, we’ll delve into everything you need to know about pipe relining.

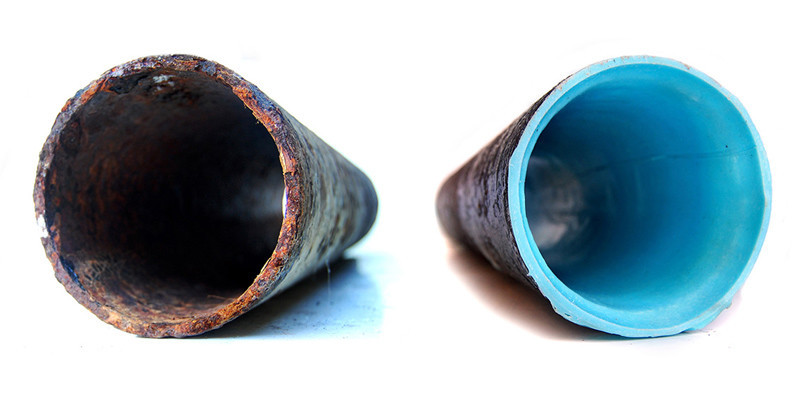

What is Pipe Relining? Pipe relining, also known as trenchless pipe rehabilitation, is a non-invasive method used to repair or rehabilitate underground pipes without the need for extensive excavation. Instead of digging up the damaged pipe, relining involves inserting a new, structurally sound liner into the existing pipe, creating a seamless, durable barrier that restores functionality and prevents further deterioration.

How Does Pipe Relining Work?

- Inspection: The process begins with a thorough inspection of the affected pipe using advanced technology such as CCTV cameras to identify the extent and location of damage, blockages, or leaks.

- Cleaning: Before relining can take place, the pipe must be cleaned and cleared of any debris, roots, or obstructions using high-pressure water jetting or mechanical cleaning equipment.

- Liner Installation: A flexible resin-saturated liner, typically made of materials like fiberglass or epoxy, is inserted into the pipe using inversion or pulling methods. Once in place, the liner is inflated and cured, adhering to the inner walls of the existing pipe.

- Curing: The curing process may involve the use of heat, UV light, or ambient temperature to harden the resin and create a durable, watertight seal. Once cured, the new liner effectively becomes a seamless, jointless pipe within the existing infrastructure.

- Final Inspection: After the liner has cured, a final inspection is conducted to ensure the integrity and effectiveness of the relined pipe. CCTV cameras may be used again to confirm that the rehabilitation process was successful.

Benefits of Pipe Relining:

- Minimal Disruption: Unlike traditional pipe repair methods that require extensive excavation and disruption to landscapes, driveways, or buildings, pipe relining is minimally invasive, reducing downtime and inconvenience for property owners.

- Cost-Effective: Pipe relining can be more cost-effective than traditional excavation methods, as it eliminates the need for labor-intensive digging and restoration, saving both time and money.

- Durable Solution: The new liner creates a seamless, durable barrier that is resistant to corrosion, leaks, and root intrusion, extending the lifespan of the rehabilitated pipe.

- Environmentally Friendly: By minimizing excavation and reducing the need for new materials, pipe relining is a more environmentally friendly solution compared to traditional pipe replacement methods.

Applications of Pipe Relining: Pipe relining can be used to rehabilitate a wide range of underground pipes, including:

- Sewer lines

- Stormwater drains

- Water supply pipes

- Industrial pipelines

- Culverts and conduits

Conclusion: Pipe relining offers a modern, efficient, and cost-effective solution for repairing and rehabilitating underground pipes without the need for extensive excavation. By minimizing disruption, reducing costs, and providing a durable, long-lasting solution, pipe relining has become increasingly popular for residential, commercial, and industrial applications.